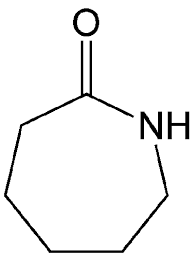

Caprolactam

GSFC has two Caprolactam Plants having rated capacities of 20000 TPA and 50000 TPA. The main raw materials are Benzene, Oleum, Ammonia, Carbon dioxide, Synthesis Gas, Sulphur dioxide, Caustic soda and Sulphuric acid.

| Specifications | |||

|---|---|---|---|

| No. | Product Characteristics | Test Method | Guaranteed Specs. |

| 01 | Solidification Point (deg C) | W : 43 : 700 | Min. 68.8 |

| 02 | Water Content(%) | W:43:701 | Max. 0.10 |

| 03 | Content of Volatile Bases (meq/Kg) | W:43:702 | Max. 0.50 |

| 04 | Content of Free-bases (meq/Kg) Content of Free-Acid (meq/Kg) | W:43:703 W:43:703 | Max. 0.10 Max. 0.05 |

| 05 | Colour Number of 50% m/m aqueous solution (APHA) | W:43:704 | Max. 5.00 |

| 06 | Permanganate No. (PN) in 1 % aq. Soln) (Seconds) | W:43:705 | Min.10000 |

| 07 | Absorbance at 290 nm (50% Soln) | W:43:706 | Max. 0.05 |

| 08 | Cyclohexanone oxime content (mg/Kg) | W:43:707 | Max.10.00 |

| 09 | Iron Content (mg/Kg) | W:43:709 | Max.0.50 |

| 10 | Water insoluble (mg/Kg) | W:43:710 | Max.10.00 |

Uses

- Caprolactam is a base material for manufacture of Nylon-6. Its applications are in the manufacture of

- Nylon-6 fibres for textile and tyre cord.

- Moulding engineering components and other extrusion profiles.

- Monomer castings.

Packing

25 Kg net sealed in low density polythylene inner bag with high density polythylene lined craft paper as outer cover.